CO2 pH Control Systems for Concrete Washout Water Treatment

We will be exhibiting at World of Concrete 2026 with Washout Watchdog Booth # 773.

We will be exhibiting at World of Concrete 2026 with Washout Watchdog Booth # 773.

We can provide a wide variety of system options depending on your specific application to neutralize concrete washout water. We have systems designed specifically for ready mix, precast, job site, hydrodemolition, potable and wastewater treatment. These systems are very affordable with a base system price of below $10,000.

Strong liquid acids like sulfuric and hydrochloric have a variety of issues including higher operating costs, easy to overshoot or undershoot the pH setpoint, dangerous to personnel and damaging to equipment. Any accidental acid spill may have to be reported. In addition, they can liberate and therefore increase heavy metals content in the washout water leading to possibly higher than acceptable discharge limits.

The ATSI CO2 system has a compact design of approx 2 ft x 2 ft x 4 ft. The combination of the CO2 gas cylinder and system can fit into a very small area at the back end of the final pit. The total weight is about 85 lbs and can be easily mounted next to a pit. In addition, the small size makes it an ideal system for mounting on a trailer or pickup and used at various sites. The control panel is NEMA 4X and the system is designed to work outdoors.

This system is placed next to the pit or tank to be treated. Connect 120 VAC power and a cylinder of CO2 and within a few minutes to a few hours a pit or tank can be pH adjusted for either reuse or disposal. Weekly maintenance on the system is less than 10 minutes for all but the most challenging processes. We make a simple system easy to operate and maintain.

Reducing the pH and making clear water are not the only benefits of treating with CO2 gas. Most cylinder CO2 is a captured waste gas. The reaction forming carbonates is mineralizing. Settling out the suspended solids in washout is sequestration. As a result, this process is an environmentally friendly. By not only cleaning the water but by capturing and mineraliziing the CO2 gas.

The systems are easy to install. However, not all pit systems and individual plant issues are the same. As a result, we can provide onsite technical support to optimize every application. We have resolved many customer washout and stormwater issues. Customer references are available upon request.

Ready Mix and Precast Plants can generate thousands of gallons of waste washout water a day. This washout water is commonly stored in washout pits and/or tanks.

Washout and Stormwater pits come in all shapes, sizes and numbers. A pit system volume can range from under a 1000 gallons to over 50,000 gallons. The number of pits can range from 1 to over 6 and typically weired together.

Washout and Stormwater can be extremely caustic with a pH as high as 13. Suspended solids (TSS) can range in the thousands. In addition, it contains heavy metals. Several studies have suggested that using concrete washout can lower the strength of concrete.

ATSI's CO2 system is designed to treat the washout pit continuously. The system monitors the pH of the water in the pit and adds CO2 gas to reduce and automatically control the pH to a desired setpoint typically below 9.0.

CO2 in water makes carbonic acid which reacts with the caustic calcium and magnesium hydroxide in the washout water and converts them into carbonates. The reaction results in a particulate which settles out of solution quickly making pH adjusted clear water. Many heavy metals are captured by the settled particulates.

The ATSI System and CO2 gas turns a washout pit from a cesspool into a swimming pool in a couple of hours. This water is clear and not exothermic. It can be used throughout the plant without compromising the strength of the concrete. Also, it discharged into the sewer or environment with the proper permit.

A concrete hydrodemolition job can generate from hundreds to tens of thousands of gallons of high pH and suspended solids (TSS) water. Quickly reducing the pH and settling out the suspended solids are the challenges. This water can be treated with the ATSI CO2 system to neutralize the pH and settle out the suspended solids creating water that is able to be discharged into the sewer or environment with the proper permit. The size, configuration and flexibility of the system makes it an ideal system to take on the road.

Porta-Pit© by Washout Watchdog is a steel encased cross-linked plastic bin specifically designed for capturing concrete washout for ready mix, precast and jobsite. The durable container is available in a variety of sizes. There is a Little Dog @1.25 cubic yards, a Big Dog @ 1.75 cubic yards and the Alpha Dog @ 3.5 cubic yards in size. The bin is a practical substitute for a washout pit at a jobsite. A lid comes with the Porta-Pits which helps prevent overflowing from rain events which can plague a jobsite washout pit system.

Porta-Pits are capable of collecting rock and sand during the washout at the plant. This durable plastic bin in front of the washout pit can reduce pit cleanouts by up to half. Mixers washout into the Porta-Pit©. The sand and gravel and some of the cementitious fines settle out. The excess water flows into the pit. When it is full of material, it can be easily dumped with a loader or forklift. This reduces the amount of slurry generated by removing the sand and gravel from the pit. Fewer cleanouts means the loader suffers less damage from entering into the slurry.

BFK offers a unique complete line of concrete reclaimers for ready mix and precast plants. These concrete reclaimers are designed to capture, wash and separate the rock and sand from washout fines with many sizes and options to fit your specific concrete reclaimer needs. BFK features a simple design, you can install, operate and maintain it. Competitive systems require installation and field service support with their product. We offer support but the BFK line of concrete reclaimers are like when you used to be able to work on your own car.

ATSI is the east coast representative forWashout Watchdog©. Washout Watchdog© manufactures a full line of gravity fed buckets and tanks designed to catch the rinse water on the mixer after pouring concrete. The above example is a rear discharge mixer with a bucket attached to the end of the chutes being washed out. When the bucket is full or washout complete. The valve can be opened and the water drains into the tank for storage for the trip back to the plant. The tank can be easily discharged into the washout pits back at the plant.

Job sites have special needs to be able to treat the washout and be able to use it on site or able to discharge into the sewer or environment. A Porta-Pit© coupled with a Jobsite CO2 system at a jobsite is a simple way to collect and treat washout generated at a jobsite. At the end of the day, the water can be treated, discharged and the Porta-Pit© emptied. The concrete doesn't stick to the bin so no oils or surface treatments required.

ATSI is a rep for Slurry Solutions, LLC Washout Flocculants are ideal for quickly settling out the suspended solids or removing color particulates in washout pits. We supply a dry type flocculant that has been specifically designed for treating washout water. The Slurry Sep floc can be applied in a mixer directly to remove color from color concrete washouts. Or directly into the washout pit to quickly settle out the residual suspended solids prior to a cleanout. Once applied, the floc is mixed thoroughly into the particulate laden washout water with our simple hydrating system . Within minutes the water becomes clear. This allows you to drain additional clear water prior to pit cleanouts.

After mucking out the pit, the slurry is placed in piles for drying. Due to the amount of residual water and rain events, this slurry may sit weeks to months to dry out enough for further processing. Also, the cost to haul off wet possibly toxic slurry can be expensive. Adding a slurry solidifier, which can turn a slurry into a solid significantly reduces that time to a matter of hours. Making a full dry possible for crushing in a matter of days.

CO2 is commonly used in the treatment of potable water to reduce the pH. However, most CO2 technologies today are lower than 95% efficient and many technologies considerably lower than that. In other words, 5% or more of the CO2 gas (depending on the injection technology) is being wasted. ATSI has designed a system that has extremely high efficiency practically no CO2 gas wasted resulting in lower operating costs.

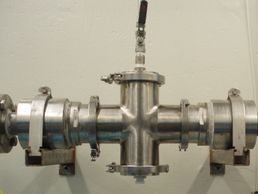

ATSI has designed a better CO2 injector with extremely high and practically instantaneous adsorption of CO2 gas. By introducing the gas at a near molecular level, it creates near infinite surface area resulting in extremely fast gas adsorption rates into the water. pH reduction is practically instantaneous. As a result, the efficiency of this technology can be as high as 99%+.

The high efficiency gas injection technology are coupled with PLC based CO2 gas control systems designed for potable water treatment plants. These systems are can maintain the pH within .1 pH continuously. We can supply feedback, feed forward and flow pacing type ph control. We can make systems capable of treating from 25 to over 3000 gpm.

We take pride in providing unique CO2 based pH control systems for every water application including Ready Mix/Precast washout and stormwater, hydrodemolition, wastewater and potable water treatment.

ATSI has been in business since 1994. We have over 30 years of industrial gas experience with all types of applications. We supply a variety of systems to treat waste, washout and potable water.

We can supply custom systems using industrial gases that are designed for every situation.

40 Diamond Street, Souderton, Pennsylvania 18964

Phone/Fax :(215) 721-2047 Email: atsi2@msn.com

Monday - Friday: 7am - 5pm

Saturday: Closed

Sunday: Closed